Anything above 1 mc in drywall would indicate a level of moisture that could compromise the integrity of the gypsum board.

Acceptable moisture content in concrete walls.

From rodney white of independent consultant on march 4 2015.

Therefore it s advisable to have a floor tested for moisture content prior to installing flooring or moisture barriers.

I have success with clear coatings over concrete floors as long as the moisture content is under 5 using a tramex moisture encounter ii.

How moisture gets into concrete.

Check the plastic for the next several days noting when moisture.

Exterior walls may use a variety of materials from wooden siding to vinyl aluminum brick and stone.

In 2016 the society for protective coatings sspc expects to publish a new guidance document field methods for the determination of moisture in concrete and masonry walls and ceilings that will describe the types of instruments used for determining moisture content of walls prior to painting including recommended test frequencies.

Microbial growth is limited when the mc of gypsum board is below 0 6 when brick is below 0 8 when wallpaper is below 10 5 and when concrete is below 5.

Moisture meters can only check the moisture near the surface of a concrete slab which is not sufficient for predicting how the slab will react to having sealant applied or other building materials installed over it.

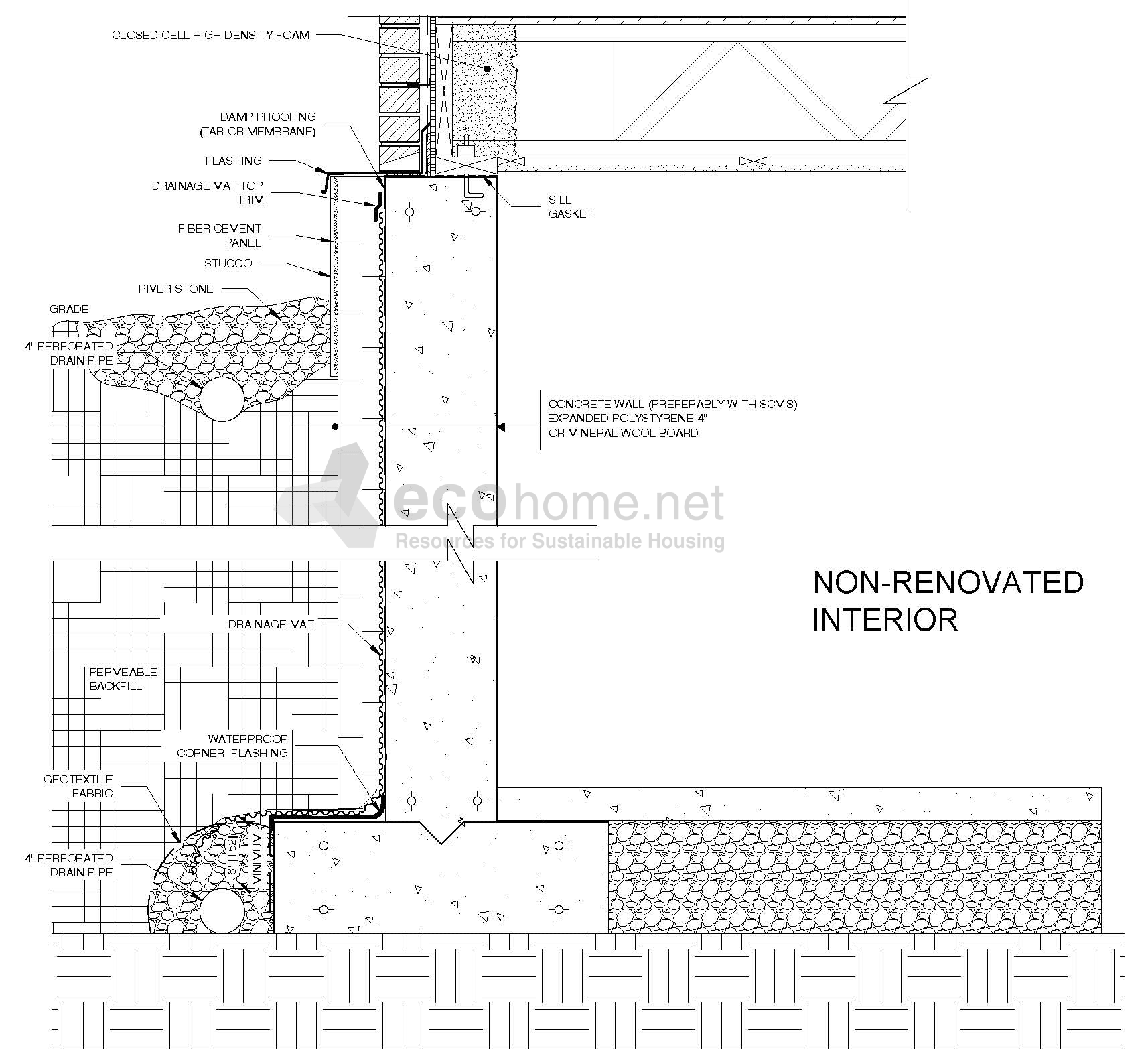

Interior moisture sources such as humidifiers unvented clothes dryers bathrooms and cooking as well as the moisture in concrete after construction.

I expect the same level would be acceptable on walls.

Exterior humid air that enters the basement and condenses on cooler surfaces.

Concrete slabs and floors can be excellent subfloor surfaces for tile and other floor coverings but too much moisture in the concrete can cause problems with flooring installations.

Concrete slabs often have thicknesses measured in feet not inches.

Generally speaking for drywall a safe moisture content mc would be less than 1 mc.

Acceptable moisture levels in concrete according to astm standard when testing via astm f2170 the rh level of a concrete slab needs to be at or below 75 unless the flooring system manufacturer provides alternate guidelines.

Moisture content is related directly to particular substrates or materials.

Seal the edges of the plastic wrap with tape.

Some flooring system manufacturers have products that can handle 95 rh or mor 2.

Moisture is transferred from the outside of the building to the basement interior by four mechanisms.

The moisture content is indicated on the grade stamp.

Tape a 12 inch by 12 inch piece of plastic wrap onto a part of the basement wall.

Most concrete moisture meters only check surface moisture.

/cdn.vox-cdn.com/uploads/chorus_image/image/65889348/iStock_1080117518.8.jpg)